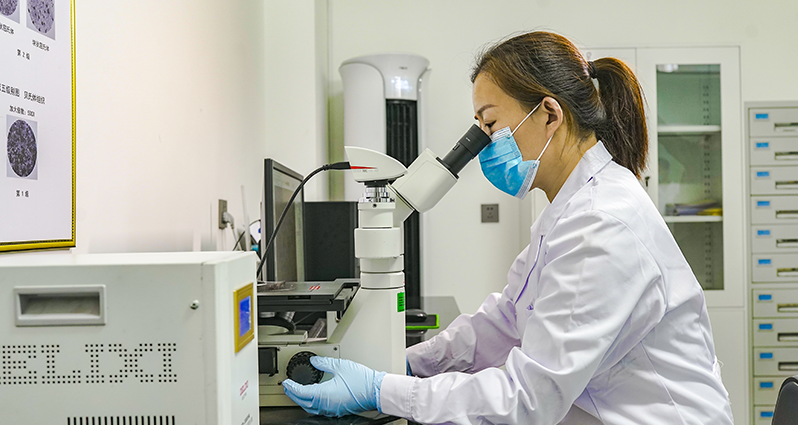

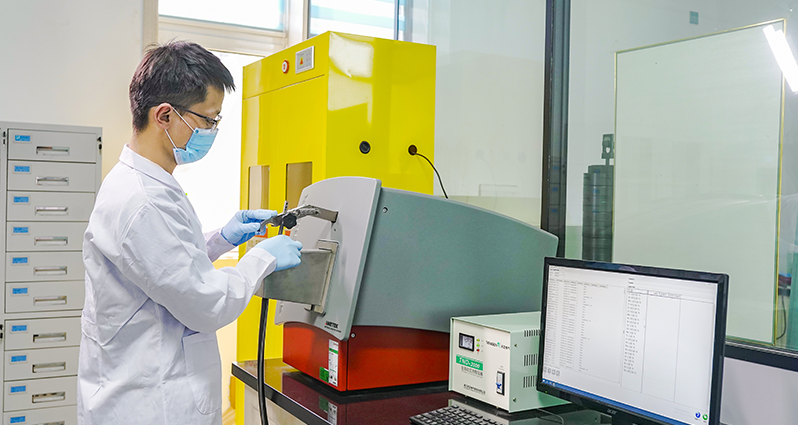

Using industry-leading testing instruments and test equipment, the control methods are synchronized with the leading international bearing brands.

Material testing files and samples are retained for 15 years, and all data are stored in the cloud.

The product components can be traced back to each raw material throughout their life cycle.