For accessories, choose RDC. No worries about quality and after-sales service.

Founded in 2017, RDC Bearing specializes in the design, research and development, manufacturing and sales of precision bearing accessories. Products include forgings, turning parts, heat-treated parts and rough grinding parts of various types of large, medium and small bearing rings.

The company has two modern production bases, covering a total area of 50,000 square meters and employing nearly 200 people. The Linxi Forging Production Base has main production workshops such as forging, annealing, turning, heat treatment, and mold accessories processing; the Wuxi Production Base has main production workshops such as turning and grinding.

The company has two modern production bases, covering a total area of 50,000 square meters and employing nearly 200 people. The Linxi forging production base has major production workshops such as forging, annealing, turning, heat treatment, and mold parts processing; the Wuxi production base has major production workshops such as turning and grinding.

Adopting extrusion-rolling process, full-contour equal-redundancy copy forging technology and optimized metal streamline to ensure the service life of the product.

Continuous fully automatic annealing line - roll-bottomed nitrogen-based protective atmosphere isothermal spheroidizing annealing furnace, this production line has passed the certification of the international leading bearing brand.

The CNC machining workshop has strong technical force, with engineering and technical personnel with many years of bearing production experience and skilled production workers.

The company has technical and R&D strengths and has passed ISO9001 quality management system certification. Since its establishment, Ridachang Bearing has continuously made innovations and breakthroughs, and its technical strength and service level have been steadily improved.

Ridachang uses high-quality raw materials of high standards and adheres to strict quality control measures. It maintains good cooperative relations with many large raw material suppliers and can select national standard materials, German standard, American standard, Japanese standard and other customized materials according to customer needs.

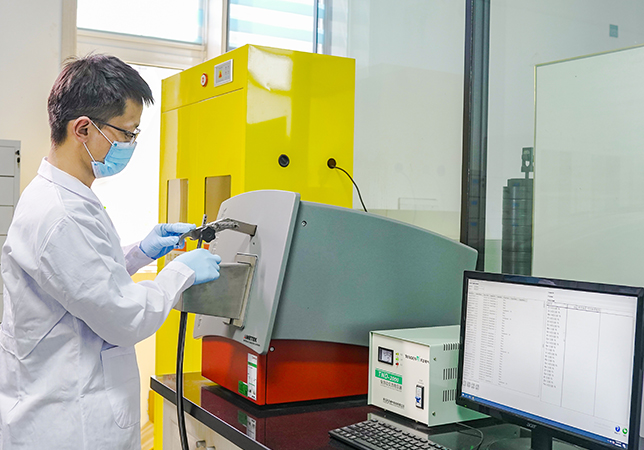

We use industry-leading testing instruments and test equipment, and our management and control methods are synchronized with those of international leading bearing brands. Material testing files and samples are retained for 15 years, and all data is stored in the cloud. The entire life cycle of product components can be traced back to each raw material.

We use advanced testing instruments and equipment to test the size, contour, shape and roughness of products in the process to strictly ensure the stability of product quality. The company’s quality testing center has high-precision imported testing and analysis instruments to strictly control product quality.